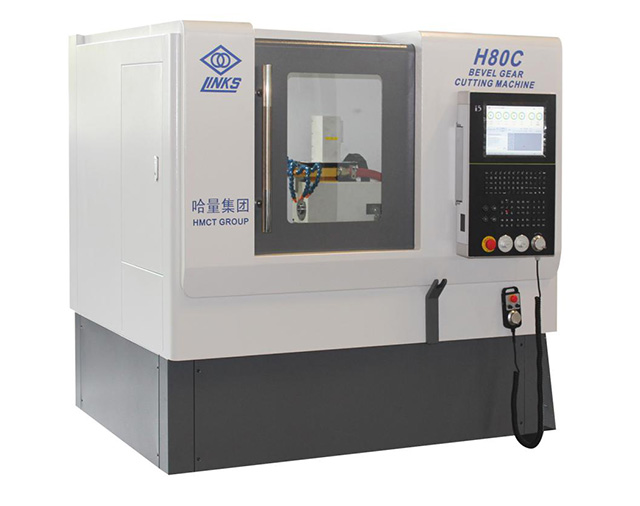

H80C CNC Spiral Bevel Gear Cutting Machine

Source:Changsha links-ks Release time:2020-05-14 09:08:03

Product characteristics

-H80C CNC Spiral Bevel Cutting Machine is a six-axis five-linkage CNC gear milling machine

- Face milling method can be used to process Gleason tooth circular bevel gear.

- The machine can process high reduced-ratio hypoid gears and end face arc tooth couplings

- It can not only be used for dry cutting with new structure cutter head, but also for using oil cooler to achieve wet cutting with traditional cutter head.

- Tool spindle and workpiece spindle adopt Direct Drive Technology

- The machine adopt Siemens s840dsl numerical Control system

- The machine can achieve automatic tool sitting and automatic allowance distribution

Matching device

- fixture

- cutterhead

- automatic tool setting device

- oil cooler

Technical parameter

| H80C |

Face milling method |

| Maximum workpiece diameter(mm) |

80 |

| modulus range |

0.7~2 |

| Maximum tooth depth(mm) |

6 |

| Maximum tooth surface width(mm) |

18 |

| tooth number |

1~100 |

| Maximum transmission ratio |

1:100 |

| working accuracy(DIN) |

5 |

| Cutter plate size |

0.8"~2" |

| Cutter shaft speed(rpm) |

6000 |

| Large end diameter of workpiece shaft(mm) |

¢31.267 |

| Workpiece shaft inner hole taper |

1:19.254 |

| Workpiece shaft through hole length(mm) |

110.5 |

| Workpiece shaft speed |

15 |

| Working table rotation angle(°) |

-900~+900 |

| Working table swing speed(rpm) |

0~32 |

| Mainframe dimension(L*W*H, mm) |

1400*3200*2000 |

| Mainframe weight(kg) |

1600 |

| floor space(L*w, mm) |

3500*4000 |