The design and manufacture technology of hypoid gear with high reduction ratio

Source:Changsha links-ks Release time:2018-01-11 18:08:00

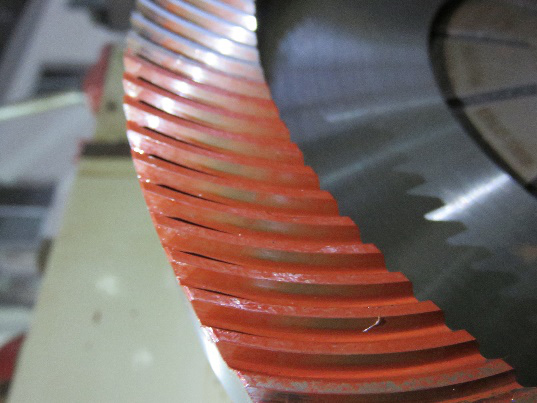

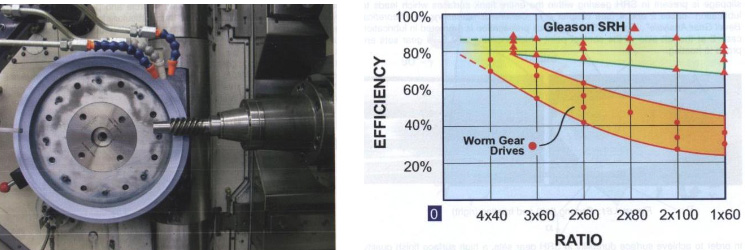

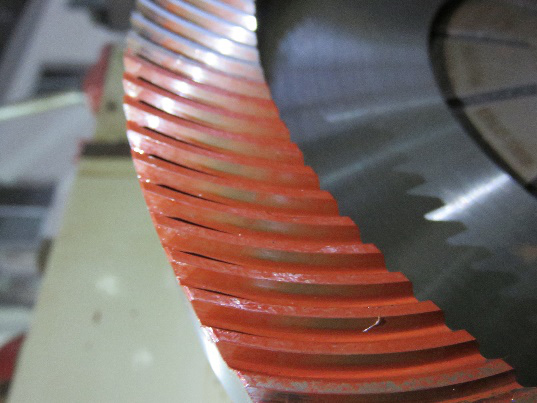

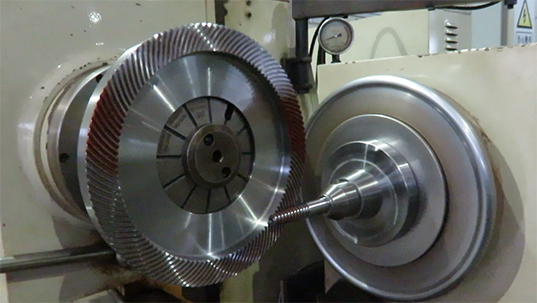

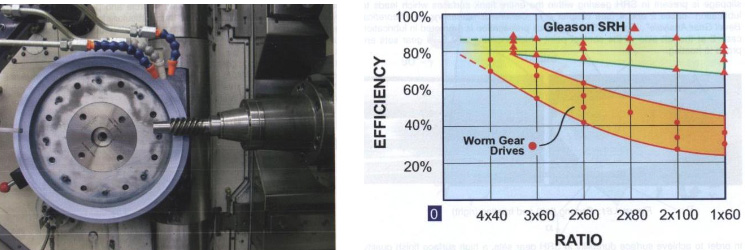

The minimum number of teeth of small gear of conventional bevel gear and hypoid gear shall not be less than 5, and the sum of teeth of large gear and small gear shall not be less than 40. But there is a special kind of hypoid gear. The number of small gears can only have one tooth, and the number of large gears can be as high as 360. This is the high reduction ratio hypoid gears, which is called SRH for short. We know that the efficiency of worm gear pair is relatively low. When the transmission ratio reaches 1:60, the efficiency is only about 40%, while the efficiency of hypoid gear with high reduction ratio can reach 80%。

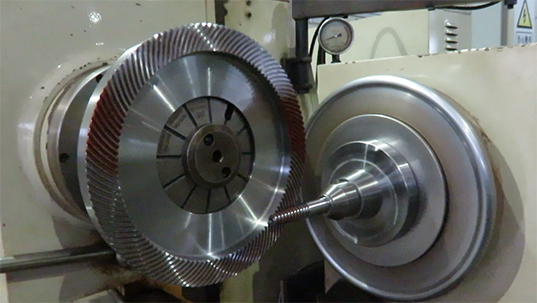

High reduction ratio gear has been monopolized by Gleason company in the United States in the past. As early as the 1950s, Gleason successfully applied it to No.116 gear milling machine, in which a pair of 5:150 high reduction ratio gears were used for the transmission of the shaking table, and a pair of 2:90 high reduction ratio gears were used on the workpiece shaft, with good application effect。

To catch up with the world, our country put forward the "made in China 2025" plan, and regard Internet plus, high-grade CNC machine tools and robots as the first and second key technologies to be vigorously developed. Many of them have to use high reduction ratio hypoid gears on joints. But this kind of gear used to have to be processed on imported Gleason machine tools or imported from Japan, which is very expensive. In order to solve this problem, Harold kaishuai successfully developed the design and processing technology of hypoid gear with high reduction ratio, and produced h350c gear milling machine and h350g gear grinding machine that can process this kind of gear. Now it has realized many sales, users use these machine tools to produce a variety of qualified high reduction ratio gear supply market, breaking the foreign technology monopoly 。